The Early Days: 1800s Innovation

Have you ever wondered about the origins of the mouthguard?

The exact origin of the mouthguard isn’t completely clear, but historians have credited its creation to boxers in the 1800’s.

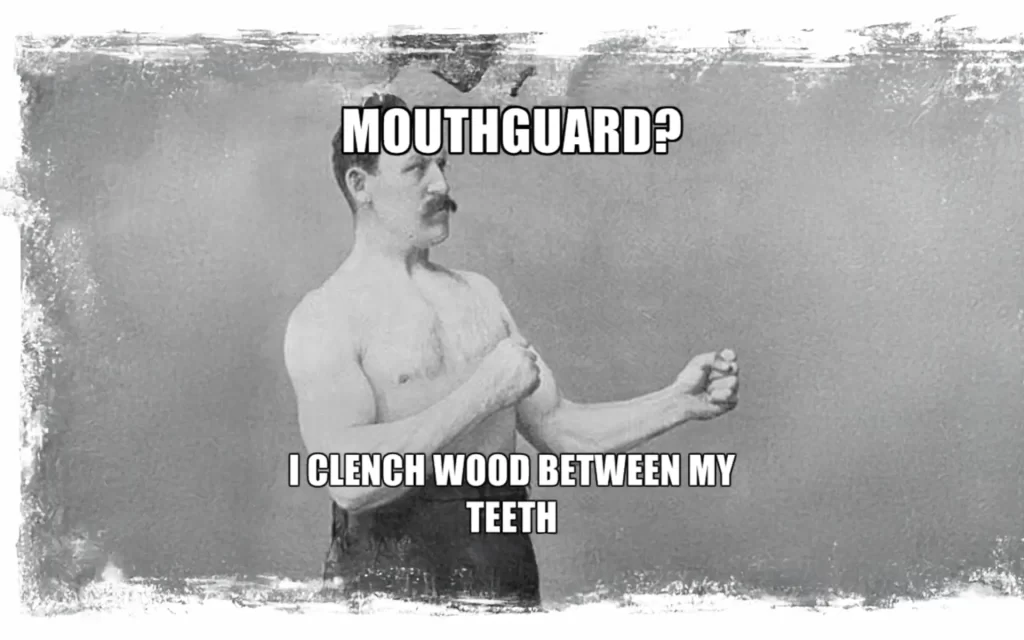

To protect themselves, boxers would bite down on pieces of wood, sponges and wool or tape to protect their teeth from what they would call “rattling” against each other. We would now call that occlusal cushioning.

The First Formal Mouthguard: 1890s

The first formal attempt at creating a mouthguard (as we know them) really appeared to be in the 1890s, when a London dentist named Woolf Krause created the “gum shield” from a gutta-percha latex material. Interestingly, Dr Krauses “gum shields” were intended to protect boxers from lip lacerations moreso than broken teeth. They were also just a single use product and again only held in place by boxers clenching on them.

His son, Philip Kraus, (himself a boxer and an assistant dentist), later expanded on his father’s design to build a mouthguard out of Vella rubber which allowed it to be more pliable than percha latex. This product was appealing as it was reusable.

Custom Mouthguards: 1930s-1940s

In 1930 Dr Clarence Mayer documented a way in which we could make custom make mouthguards using wax and rubber impressions, and in 1947 a Los Angeles dentist named Rodney O Lilyquist ( who was later coined the father of “modern mouthguards”), invented a technique using acrylic resin to form an acrylic mouthguard which fitted the upper and lower teeth perfectly to make them less obtrusive and more protective.

The Birth of Dental Fabrication: 1950s

In the 1950’s William Godwin worked on vacuum forming Ethylene Vinyl Acetate (or EVA) over casts of athletes teeth. This saw the beginning of dental fabrication ( dental made mouthguards) as we know them.

It was also around this time that the American Dental Association started to really promote the protective benefits of wearing a mouthguard.

The Boil & Bite Revolution: 1960s

Fast forward a decade (1960) and Dr AG Jacobs developed the first mouldable “boil & bite” type mouthguard made from EVA, that athletes could form for themselves. This mouldable innovation opened up a whole new era for mouthguards, because they were now more accessible to everyone. This accessibility greatly increased the success of the formal rule changes that were about to come recommending mouthguards be used for all contact sports.

By 1962, all high school football players in the US were required to wear mouthguards, and currently the American Dental Association advise that mouthguards be used in 29 different sports.

Six Decades of EVA Development

Since then, which is essentially the last 60 years, we have continued to use Ethylene Vinyl acetate (EVA) for both technician and commercial (or over-the- counter) mouldable mouthguards.

We have perfected the dental fabrication procedure for dental technicians through using impressions or scans to make working models of teeth and then vacuum forming or pressure forming machines to custom fit the material over the models.

We have tried and tested a variety of different polymers (or plastics) and have discussed and researched the pros and cons of incorporating hard inserts into mouthguards to disperse impact energy, air spaces into mouthguards to better absorb impact energy and the combination of hard inserts and an air pocket all with the aim of improving a mouthguards protective benefits.

We have seen really promising results with these variations, with EVA ultimately continuing to hold its standing as our “go to” mouthguard material.

Recently (and by that we mean in the last 15 years), a new material has emerged in the medical sector with excellent mouldability at safe temperatures but substantially stiffer than EVA.

We have embraced the structural benefits of this new polymer to engineer the inner layer of NeoMorph in a unique way. We call this NCore®. It is thin, moulds exceptionally well and provides the opportunity to efficiently spread the energy of an impact, while the outer layers provide compliance for energy absorption and detailed fit.

The introduction of this new material is the difference between Neomorph and all other over-the-counter mouldable mouthguards. NCore® is super mouldable which provides Neomorph with its superior custom fit, comfort, retention and protective quality.

We now have another material in our arsenal to better protect athletes. Neomorph’s unique structure offers a new level of protection.